Production

Introduction

Organisations will adopt a variety of techniques to produce their goods or services. The technique adopted will depend on a number of factors including;

- The product or service

- Quality of the product or service

- Quantity of the product or service

- Size of the organisation

- The type of organisation

- The organisation's resources

- Legislation applicable to the organisation

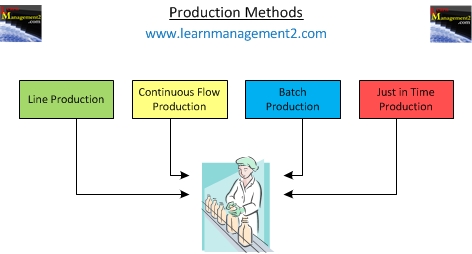

The most common methods of production include Line Production, Continuous flow production, Batch Production and Just in Time Production.

Below is a LearnManagement2.com diagram illustrating different production methods. Click on the diagram if you'd like to read our article about production methods.

Adding Value

The aim of all production methods is to add value (value chain analysis). Adding value is the process of converting the input to an output so that it’s desirability to the customer increases. The input is the product or service at the start of the production process. The output is the product or service at the end of the production process.

Line Production

Just as the name suggests line production is producing goods along a line of production. The goods will be passed along a line containing different stages. At each stage in the line the goods will be altered. Often a person/group of people will be responsible for just one stage in the process. Car assembly or fast food “drive thrus” (drive through), often adopt Line production as identical products are produced each day. Nowadays some organisations will employ robots rather than people to undertake the stages in line production. Robots are believed to be more efficient and unlike humans will not get bored and cause errors.

Continuous Flow Production (CFP)

This is simply adopting line production 24 hours day/seven days a week, using automatic equipment. The automatic equipment will operate in the same manner day in day out. The ability to work in this manner is another advantage robots/machinery have over humans. CFP does not involve humans so it is not used in the service industry unlike line production.

Batch Production

This is the method employed when the organisation needs to produce a fixed amount of each of the type of goods it produces. In this instance production technique and resources will be adapted, to produce the product required and to produce just the amount required. A good example is a pizza factory. Let’s imagine the factory produces 150 pepperoni pizzas, 265 ham and pineapple pizzas and 75 cheese and tomato pizzas each day. Each batch (or variety) of pizza have its own ingredients, cooking times and production method. When the factory switches from the production of one type of pizza to another, it will need to change its production methods. Some of the tasks for one type of bread can be completed at the same time as producing the other types of bread such as making dough for the cheese and tomato pizza, whilst waiting for the pepperoni pizzas to cook. However the factory will have to be careful to ensure that they do not confuse the production of one type of pizza with the production of another.

Just In Time Production

This method of production generates goods/services just in time for them to be sold rather than preparing them months or weeks in advance. To save storage costs, the parts needed to make the end product will arrive just before they are used to manufacture the product. This means that the production process is carefully planned and organised. Production must be efficient and speedy otherwise the goods will not be manufactured for the customer. Conversely if there are no or few orders production will slow down or stop altogether.