Total Quality Management

From the 1980's Total Quality Management was adopted by a number of organisations. TQM requires the whole of the organisation to adopt the culture of quality. In a TQM organisation quality will dictate the decisions, tasks and processes. A TQM organisation is committed at all levels within every department/function to continuously improve quality. In order to fulfil this commitment every single employee in the organisation will need to accept the challenge of continual quality improvement.

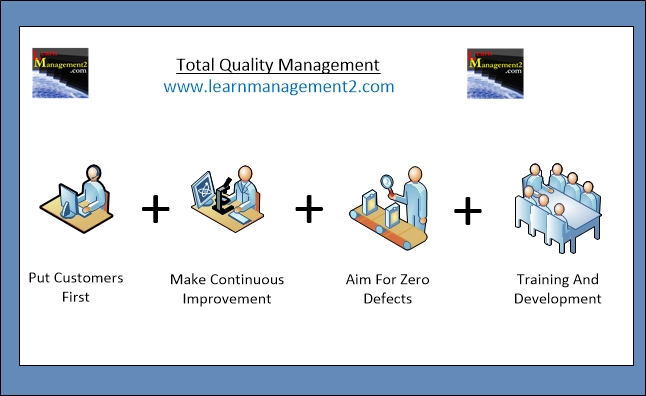

Total Quality Management (TQM) Components

TQM has four basic components

- Put customers first

- Make Continuous Improvement

- Aim for zero defects

- Training and development

Lets discuss each of the four Total Quality Management Components

Put Customers First

A quality product or service satisfies customer’s needs and expectations. Whether a product or service is of high or low quality, will be decided by how it made the consumer feel and whether consumer expectations were satisfied or exceeded. Our article about quality provides you with more information about how to define quality. If customers are not put first, then customer expectations will be difficult to satisfy and consequently quality will not be achieved.

Putting Customers First Examples

Customers can be put first through a variety of initiatives including:

- Undertaking market research to discover consumer needs so that the organisation can develop products and services that exceed their consumer's needs. Read our article about Market Research to learn about market research and decision making.

- Looking after all customers whether internal or external - Internal customers are employees of the organisation and are known as customers when they approach each other for a service. External customers are all non-employees (of the organisation) that approach the organisation in connection with a service or product.

- Effective customer care systems - Customer care systems are all systems that support customer service; they include customer advice, after sales support, product warranties and in store facilities such as parent and baby rooms, shoe fitting services and waiting rooms.

- Ensuring that all service standards are met - If you are an organisation that meets its service standards customers know that they can rely on you especially when it matters. There is little value in setting service standards if you do not meet them. This creates a bad impression and says to customers that you do not value them enough.

- Listening to customer views and opinions - Responding to customer views including resolving customer complaints in a manner that satisfies their expectations. Once customer complaints are resolved they should be analysed to prevent future recurrence.

Make Continuous Improvement

The Japanese term “Kaizen” has contributed to this component. Kaizen believes that there are no limits to continuous improvement. This means that a TQM organisation will continuously strive to improve their product/service and increase the quality standards. A TQM organisation will also view change positively whether the change involves a process change or a change in customer needs and expectations; this is because changes will enable the organisation to develop and explore quality.